Register for free and continue reading

Join our growing army of changemakers and get unlimited access to our premium content

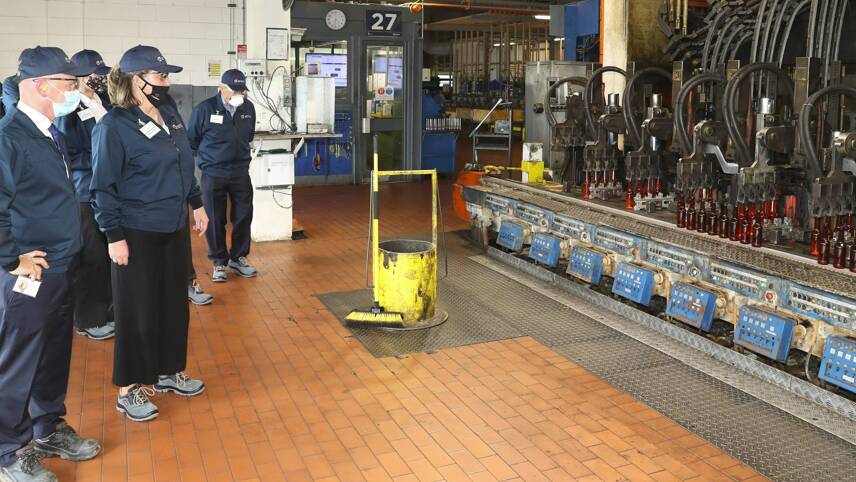

Pictured: Operations at Encirc's plant near Ellesmere Port

HyNet North West, a collaborative initiative developing a low-carbon industrial cluster around the River Dee and River Mersey, has today (14 April) confirmed that 28 manufacturers have signed Memorandum of Understanding (MoU) documents on the procurement of hydrogen.

Companies included in this cohort include Pilkington Glass and Unilever, which have both begun trials of hydrogen-powered processes at their facilities in the Liverpool City Region. Unilever’s trials began last month, while Pilkington Glass’s began last year. Both trials received funding from the UK Government.

Other companies with MoUs with Hynet include food and beverage giants Kelloggs, Pepsico and Kraft-Heinz; automaker Jaguar Land Rover (JLR); glass bottle manufacturer Encirc and hygiene and health business Essity, which owns brands such as Bodyform, Cushelle and Plenty.

HyNet is working to bring a network of solutions for decarbonising heavy industry and transport online this decade. On hydrogen, it has decided to progress a blue hydrogen facility at Ellesmere Port. Blue hydrogen is produced by reforming natural gas and then capturing process emissions using man-made carbon capture and storage (CCS) technologies.

HyNet is also working to develop solar and wind generation sites, which may be suitable for green hydrogen production. However, it is yet to confirm specific projects. Green hydrogen is produced using electrolysis that is powered with renewable electricity.

“As renewable electricity generation expands, HyNet’s infrastructure can also increasingly be used to create, transport and store hydrogen made from renewable electricity,” said HyNet’s project director David Parkin. “ In the meantime, we must decarbonise the natural gas that industry relies on today using UK technology, including CCS, to produce low-carbon hydrogen.”

The UK Government is supporting both blue and green hydrogen in what it is describing as a “twin-track” approach. The UK’s Hydrogen Strategy, published last August, committed the UK to hosting at least 5GW of blue and green hydrogen production capacity by 2030. That target was subsequently increased to 10GW in the Energy Security Strategy, which was published last week.

Blue, green and grey

Hydrogen is often touted as a low-carbon solution for hard-to-abate sectors like industrials, shipping, rail and heating. This is because it produces no greenhouse gas emissions at the point of combustion. A further benefit is that hydrogen can be stored, thus contributing to maintaining energy security as more intermittent renewable electricity generation comes online.

However, it is not, in and of itself, low-carbon. More than 90% of the hydrogen produced globally at present is ‘grey’, meaning it is produced using unabated fossil fuels. Nations like the UK, with net-zero targets and barely any hydrogen production capacity, are broadly striving to ensure that new generation capacity is either blue or green.

As man-made CCS solutions are in their relative commercial infancy, questions continue to be raised about the actual low-carbon benefits of blue hydrogen. Without efficient CCS, the blue hydrogen life-cycle may be higher than that of natural gas, by some calculations. Moreover, blue hydrogen production facilities cannot easily be retrofitted to produce green hydrogen.

Blue hydrogen can only be tolerated if the carbon capture works. As no one has a commercial scale plant working anywhere in the world you can call me sceptical. Of course they can pursue and develop but should only be permitted on basis of ccs working, if not it’s a complete con and worse than just a waste of money.

Even if ccs can be made to work reliably, my understanding is it it’s very energy intensive (ie will be expensive) do best to have a true low cost/low carbon alternative on stand by.