Register for free and continue reading

Join our growing army of changemakers and get unlimited access to our premium content

Blockchain creates a tamper-proof

Blockchain solution provider Circularise announced on Tuesday (8 February) that it will embark on a three-year project to create the system, which will be called the Circular System for Assessing Rare Earth Sustainability (CSyARES).

The system will enable data from rare earth supply chains to be recorded on a digital, tamper-proof ledger – thus enabling businesses to verify claims about tackling prevalent issues including pollution and human rights abuses.

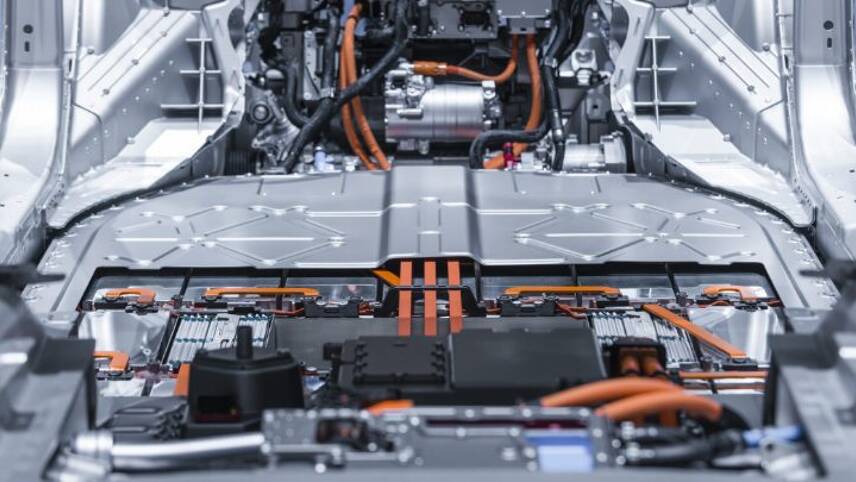

This will be particularly important as demand for these materials increases in line with the transition to EVs in the global north, which governments are keen to ensure does not result in unintended sustainability consequences overseas. Annual global demand for rare earths has doubled over the past 15 years and now stands at 125,000 tonnes. By some estimates, it will surpass 315,000 tonnes in 2030.

Also co-developing the system are the Rare Earth Industry Association (REIA), which is providing its expertise on sustainability standards; London-based life cycle assessment provider Minviro; German robotic solutions provider BEC GmbH and Danish water tech firm Grundfos. Funding is being jointly provided by the EU and by EIT RawMaterials, the largest consortium in the global raw materials sector, specialising in innovation acceleration.

“With CSyARES, we see a big potential in developing solutions for suppliers, brands, and industry as a whole to measure, understand and reduce the climate impact of rare earth metals,” said Circularise’s founder Jordi de Vos.

“As corporations and governments work toward a sustainable future, climate supply chain traceability software that leverages data and blockchain to measure environmental impact can help increase the secondary resource efficiency and accelerate the transition to a circular economy.”

To this latter point, the system will have the capability to trace both virgin raw material supply chains and supply chains for reclaimed and recycled materials.

Closing the loop

As well as ensuring sustainable raw material supply chains, growing the supply of – and demand for – recycled metals and minerals for EVs will be critical to ensuring the sector can scale sustainably. But in nations including the UK, the EV stock is growing faster than recycling infrastructure, laying the foundations for a future resource challenge. Many UK manufacturers currently export used batteries to European facilities for recycling.

Last week, Britishvolt, which is developing a Gigafactory in Blyth, announced a joint venture with mining giant Glencore, focused on the development of battery recycling systems. The two firms were already working together on the procurement of certified raw cobalt.

Glencore develop a new lithium-ion battery recycling plant at its Britannia Refined Metals facility in Northfleet. This facility will process all of Britishvolt’s manufacturing scrap in the first instance and, in time, will recycle portable electronics batteries and full EV packs, with Britishvolt getting first dibs on purchasing the recycled content.

Glencore is expecting the plant to have a processing capacity of at least 10,000 tonnes per year and is hoping for it to come online by mid-2023. It has pledged to power the facility using 100% renewable energy.

As well as developing the recycling plant, Britishvolt and Glencore will launch a new research programme focusing on next-generation EV battery recycling.

“Recycling is key to a successful energy transition and has always been a major part of Britishvolt’s business model,” said the firm’s global chief operating officer Timon Orlob.

“We’ve been looking for the perfect partner to help kick start a UK battery recycling industry and FTSE 100-listed Glencore has expert historical experience in recycling. This joint venture will help us both to create a truly sustainable battery value-chain, create jobs and develop new battery recycling technologies.”

Britishvolt has already broken ground at the Blyth Power Station site and is planning to bring the Gigaplant online in 2023.

The news comes after waste and resource management giant Veolia announced that it will develop plans for an EV battery recycling facility in Minworth, West Midlands. Veolia is hoping to bring that plant online in 2024.

Sarah George

Please login or Register to leave a comment.