Register for free and continue reading

Join our growing army of changemakers and get unlimited access to our premium content

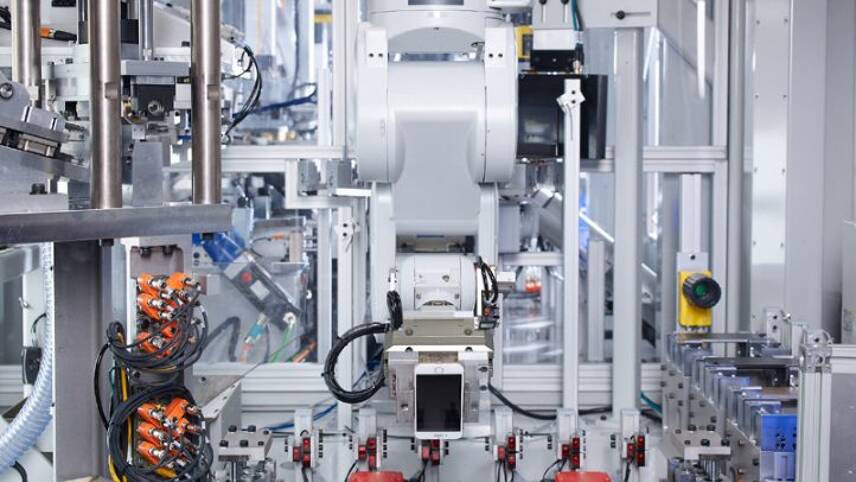

Apple's Daisy recycling robot is capable of disassembling 200 iPhones per hour

The new 9,000 sqft Material Recovery Lab will be based in Austin, Texas, and will host engineering teams and academics working to develop and scale-up innovative recycling solutions which use robotics, machine learning and artificial intelligence (AI) to close the loop on technology waste.

Work at the facility will cover three key focus areas – optimising existing recycling practices, improving the ability to disassemble devices and developing the next generation of recycling technologies. Apple will share findings from the centre with the recycling industry and its competitors in a bid to spur global progress on e-waste.

The unveiling of the facility was confirmed in Apple’s latest sustainability report, which reveals, for the first time, the environmental impact of its updated “Daisy” recycling robot system.

Launched in April 2018 to mark Earth Day, the AI-powered system was initially able to disassemble nine iPhone models to recover materials that traditional recyclers couldn’t. According to the sustainability report, Apple’s stock of Daisy devices is now capable of recognising and disassembling 15 different iPhone models and collectively processed more than one million devices last year.

Devices to be processed through the Daisy system are sourced through Apple’s network of 5,000 stores and service providers with take-back systems. Before they are sent to the robotics facilities, however, they are first examined to see whether they can be refurbished and resold. During 2018, Apple refurbished 7.8 million devices.

In order to collect more used devices as it strives to meet an ongoing aim of building devices using 100% closed-loop materials, Apple has now confirmed plans to roll-out its customer take-back scheme to retail chains Best Buy and KPN, in the US and the Netherlands respectively.

The firm already uses 100% recycled tin in the logic boards of 11 different product lines and recently transitioned to a 100% recycled aluminium alloy for its MacBook Air and Mac Mini models, but hopes moves made during 2019 and beyond will enable it to close the loop on cobalt and copper as well. Its overarching aim, given the emissions intensity and human rights issues associated with metal extraction, is to “one day stop mining the earth altogether”.

“Advanced recycling must become an important part of the electronics supply chain, and Apple is pioneering a new path to help push our industry forward,” Apple’s vice president for environment, policy and social initiatives Lisa Jackson said.

“We work hard to design products that our customers can rely on for a long time. When it comes time to recycle them, we hope that the convenience and benefit of our programmes will encourage everyone to bring in their old devices.”

Solar-heavy supply chains

As well as information on its resource efficiency and waste management actions, Apple’s sustainability report also documents progress on its low-carbon and renewable energy initiatives.

The company announced in 2018 that it had achieved the milestone of powering all of its global facilities with 100% renewable energy, with the sustainability report revealing that two-thirds of this power was generated at Apple-owned renewables facilities.

It is now striving to encourage suppliers to follow suit. The report reveals that Apple is set to “far exceed” its 2020 goal of bringing 4GW of new clean energy capacity into its global supply chains, having engaged 44 key suppliers to date. This trajectory, the document claims, puts Apple on track to add 5GW of supply chain renewables capacity within the next 18 months.

In a drive to engage other large corporates with the transition to low-carbon energy systems, Apple last year collaborated with cloud services firm Akamai, reinsurer Swiss Re and e-commerce brand Etsy to develop two new wind and solar farms in the US.

Sarah George

Please login or Register to leave a comment.