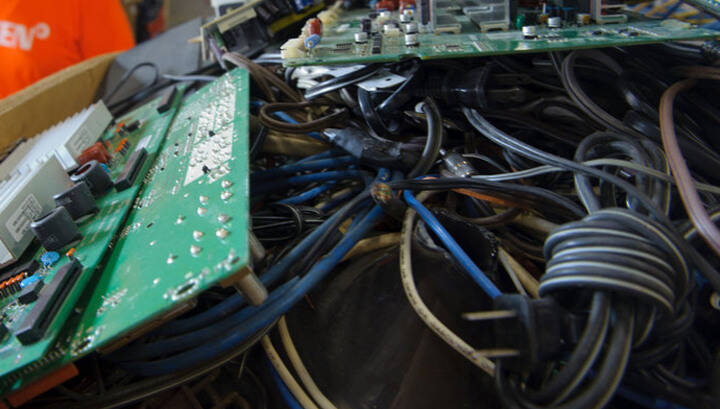

Effective, fully compliant handling and management of waste electrical and electronic equipment, as well as being a regulatory requirement in the UK, can also contribute to the achievement of a company’s objectives for cost effective resource efficiency and corporate social responsibility. These two factors are critical to maintaining and enhancing brand reputation.

The objective of the audit was to ensure that the data gathering process for the Waste Electrical and Electronic Equipment Regulations (WEEE), European Recycling Platform (ERP) and battery producer responsibility schemes was as accurate and efficient as possible.

Regulatory compliance is essential to this customer’s continuity of business operations as leading provider of mobile communications for both corporates and household consumers. The timing of this audit was also critical given the imminent changes to the WEEE regulations introduced in January 2019. The customer specifically wanted answers to questions about their interpretation of the legislative requirements, data collation, submission of data to Producer Compliance Schemes and their influence on reducing resource use.

Robust investigations ….

JRP Solutions cross referenced each compliance registration requirement and produced a producer responsibility audit gap analysis and provided a detailed review of the customer’s performance, risks of non-compliance and opportunities for performance improvement. Each requirement was qualitatively reviewed by an independent, lead-auditor qualified specialist as well as quantitively reviewed against evidenced documentation.

Following a review of the customer’s documentation covering internal processes and procedures, face-to-face interviews with internal team members were also undertaken. This enabled a full review of all aspects of compliance.

Additionally, JRP carried out four store visits to investigate how well retail outlets were complying with the regulations, including how take back of WEEE and batteries was being actively promoted in compliance with the regulations. JRP were able to investigate both the front and back of house areas in each store, providing good insights into how well internal and customer-facing processes are managed.

.. produce positive results

As a result of their investigations, JRP identified a range of areas for improvement, including recommendations for the wider ISO 14001 environmental policy such as improving take back procedures in stores and having a defined procedure for data collection at retail outlets. Other potential areas for improvement included promotion of take back schemes, a formalised procedure detailing the full cycle of WEEE and battery reporting, packaging returns and communication.

If you have questions or need support to ensure your organisation is fully compliant, please call us on 0800 6127 567 or email info@jrpsolutions.com.

N.B. The information contained in this entry is provided by the above supplier, and does not necessarily reflect the views and opinions of the publisher