Register for free and continue reading

Join our growing army of changemakers and get unlimited access to our premium content

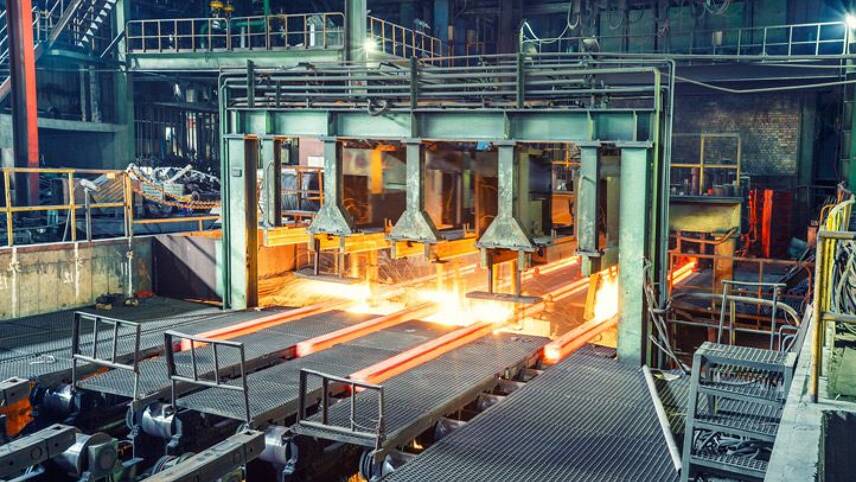

The foundation industries account for 15% of the UK’s emissions, according to Innovate UK, and are worth around £52bn to the economy

The Energy and Climate Intelligence Unit (ECIU) has today (7 March) reported that the UK falling further behind in the race to develop green steel plants. The ECIU has found that in 2021, the UK had zero planned green steel projects, compared to 23 in the EU. Overall, the UK has one project compared to 38 in the EU.

Around 10 EU plants have started producing green steel with renewable energy and green hydrogen, made through electrolysis from renewable electricity and producing no emissions. Since 2021, the number of these green steel projects has doubled, either in the form of new sites or older ones switching from blue hydrogen in the past two years.

The UK, on the other hand, has one planned project at British Steel’s Scunthorpe plant which is part of the Zero Carbon Humber initiative. The project would use blue hydrogen – commonly produced from gas and combined with carbon capture technologies. However, the Russian invasion of Ukraine has seen more than $70bn invested in green hydrogen initiatives globally as many nations have balked at the rising costs of blue hydrogen.

The ECIU’s energy analyst Jess Ralston said: “With car manufacturers starting to seek out sources of green steel to back their EV expansions, will the UK be in a position to compete? The gas crisis has spurred a dash from the US and EU to build green industries. Does the Chancellor have something up his sleeve to ensure the UK doesn’t fall further behind on steel?”

UK issues

At the start of the year, it emerged that the UK Government was planning two grants of £300m each for British Steel and Tata Steel, with requirements to cut carbon. It is also allegedly set to consult on a carbon border tax for steel.

A letter from the sector to MPs detailed how “crippling energy costs, carbon taxes, lost markets, lower demand, and open market access for imported steel” have compounded to leave the sector “a whisker away from collapse”. Liberty Steel this month announced plants in West Bromwich, Newport and Tredegar would be made idle as part of a restructuring of its business, partly due to high energy costs.

Around 2% of the UK’s total emissions or 14% of its industrial emissions are attributable to iron and steel production.

British Steel has previously pressed for up to £1bn of Government support to adopt technologies that will enable it to align with the UK’s legally binding net-zero carbon target for 2050. Tata Steel is reportedly pricing the transition of its Port Talbot steelworks to net-zero at up to £3bn.

More broadly, trade body UK Steel has warned that steelmakers in the UK are being deterred from shifting to lower-carbon, electricity-powered operations by prohibitively high industrial electricity prices.

The organisation, convened by the manufacturing sector organisation Make UK, outlined its vision for aligning the steel sector with the UK’s 2050 net-zero target. The sector is targeting a 95% reduction in emissions within this timeframe and will then ‘net’ the residual emissions using approaches such as offsetting. However, spiraling energy costs have now become a deterrent for the sector.

Businesses are striving to increase green steel use and production globally, however. Members of the SteelZero initiative, for example, have pledged to buy and use 50% lower-emission steel by 2030, supporting a long-term ambition of using 100% net-zero steel by 2050.

Thanks for sharing this article, indeed, green steel availability remains challenge for the industry.