Would you like to know how to generate economic savings for your boiling system?

Download Kurita’s eBook to learn more.

Increasing productivity with Kurita’s Cetamine™ Technology

Cetamine™ is a technology based on film-forming substances which creates a protective film against corrosion in boilers, steam generators, and closed systems. By this, systems that are treated with Cetamine™ can be operated not just safely but also economically because Cetamine™ increases the efficiency. Heat transfer surfaces are cleaned and kept clean so that the heat transfer is increased. By not adding any inorganic components such as phosphates or sulfites the COC (cycle of concentration) of a boiler can usually be increased, which reduces the blow-down water amount by ca. 50% and more. Less blow-down leads to less fresh make-up water that needs to be prepared and added to the system. This already provides huge savings in water and the related costs for water preparation. But even higher savings are achieved due to savings in energy due to less water that needs to be heated. For example, a boiler system operating at 20 bars and generating 100 t/h of steam can save more than 250 k€ per year by changing to Cetamine™ and reducing the blow-down rate by 50%. At the same time, CO2 emission will be reduced by ca. 700 tons per year and 8,500 m³ of water will be saved yearly.

Customer success stories with Cetamine™ Technology

More than 5,000 boilers and closed systems are treated with Cetamine™ products based on film-forming substances.

A vast number of power plants are treated with Cetamine™. In recent years the operational mode of such plants has changed completely. Systems designed for continuous operation are currently experiencing discontinuity with hundreds of start-ups and shutdown cycles throughout the year. This leads to technical problems in many units. Steam purity requirements are not achieved timely, and the turbine needs to be bypassed, representing valuable losses of electricity that cannot be produced.

Applying Cetamine™ in steam generators in the power industry allows discontinuous system operation as the Cetamine™-film remains stable during short and long-term shut-down periods. Especially after a restart, the generated steam is extremely clean and can be sent to the turbine directly without any bypass period.

Cetamine™: The Go-To Solution for High-Pressure Systems

Cetamine™ is also applied in many massive high-pressure systems e. g., in refineries, petrochemical plants, and ammonia production plants. An ammonia production plant in the Netherlands suffered from multiple severe tube failures in their waste heat boilers in the past under the conventional treatment program based on phosphates. Since changing to Cetamine™ in 2013, the technical problems in the water/steam cycle have been solved, and no other tube failures have occurred. The blow-down rate of the high-pressure steam drum has been reduced by 70 %, which leads to savings of a couple of hundred thousand euros per year on this site.

Cetamine™: The Ideal Solution for Low-Pressure Boilers

Lastly, Cetamine™ is utilized in a multitude of low-pressure boilers.

A chemical industry customer in France operates four boilers at just above 20 bars. The major challenge of this plant was discontinuous operation and poor treatment results with conventional products based on phosphates and sulfites. When this customer changed to Cetamine™ Technology in 2010, the technical parameters improved significantly, which allowed reducing the blow-down by more than 60 %. Together with further improvements, this customer saves a couple of hundred thousand euros per year, and the carbon dioxide emission is reduced by 750 tons annually.

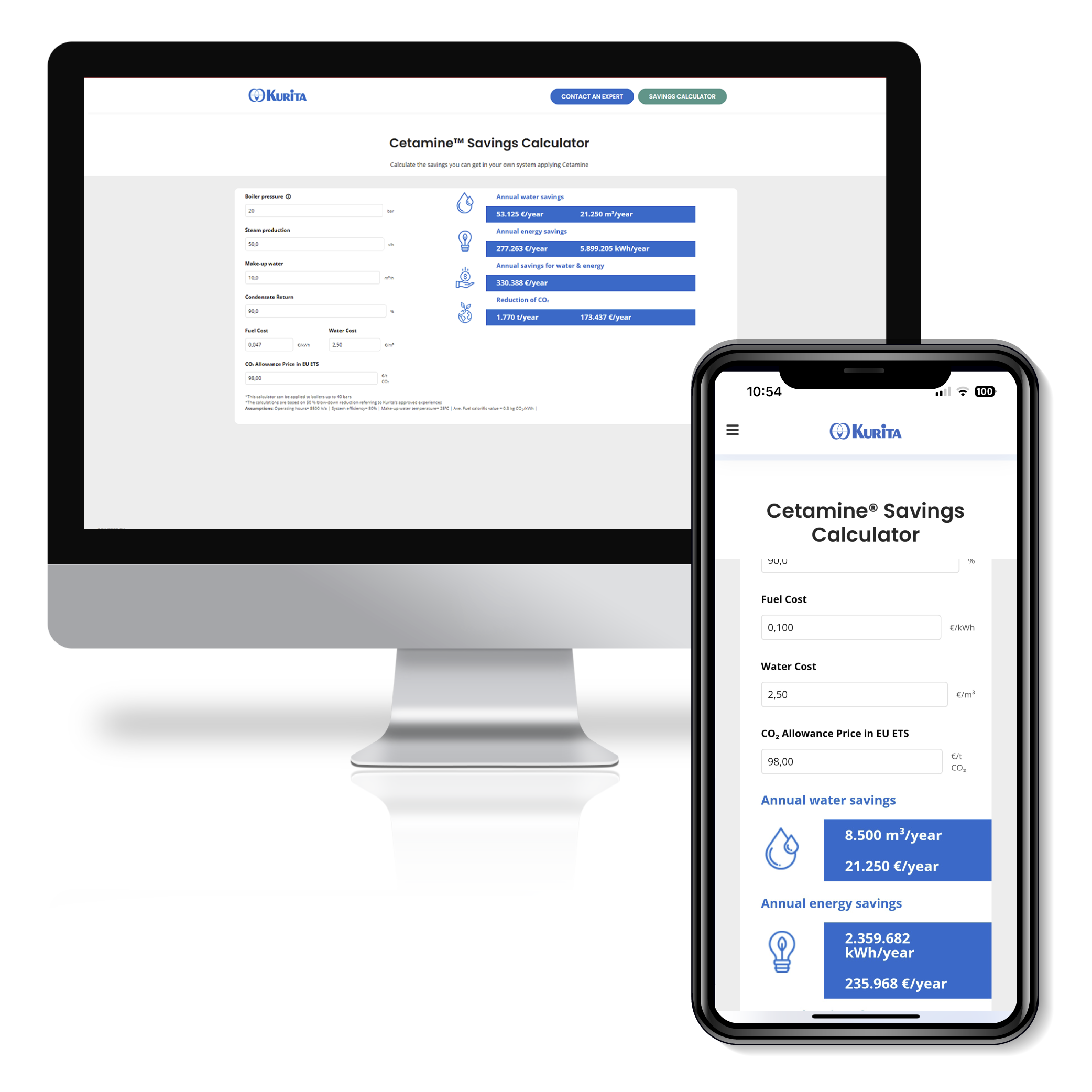

Maximize your productivity and energy efficiency by taking the first step and using the Cetamine™ Savings Calculator.

Begin optimizing your boiling system immediately!

For more information or assessment, please contact us. We are pleased to help you.

Contact us:

Kurita Europe GmbH, Theodor-Heuss-Anlage 2, 68165 Mannheim, Germany

Phone: +49 621 1218 3000

E-Mail: kuritaeurope@kurita-water.com

Webpage: www.kurita-csv.com/cetamine/

N.B. The information contained in this entry is provided by the above supplier, and does not necessarily reflect the views and opinions of the publisher