Register for free and continue reading

Join our growing army of changemakers and get unlimited access to our premium content

Innovations featured this month could help solve sustainability challenges like the intermittency of renewable electricity generation

In Back to the Future Part II, people zipped around cities in flying cars. That film, released in 1989, was set in the year 2015. The world may have failed to live up to this Hollywood prediction, but now, in 2022, flying cars are becoming a reality. Our first innovation of the month focuses on the recent public exhibition flight of an electric-powered, low-altitude, road-to-air vehicle.

Elsewhere, global innovators are understandably focusing on energy. Wind and hydrogen are both well-known as promising energy sources for the future. And this month we have seen developments in both. A new bladeless wind turbine provides near-constant power by working with wind speeds as low as five miles per hour. Meanwhile, oil-eating microbes are being deployed in the US to create ‘gold’ hydrogen from spent oil and gas wells. And, across the pond in Sweden, plans for a giant, integrated green hydrogen and steel plant are moving forward with new funding.

We have also seen some innovators experimenting with less well-known energy sources. Decentralised piezoelectric converters could revolutionise wave energy – and be used in a range of other contexts to boot. And, in France, a start-up is re-visiting osmotic energy – a power source first theorised in the 1970s.

Finally, in the UK, a start-up is digitising one of the world’s most polluting industries, concrete, in order to improve efficiency and reduce emissions. Read on for our Green Innovations of the Month!

Electric flying car completes public exhibition flight

Image: XPENG

Flying cars are becoming a reality. China’s XPENG mobility technology experts recently completed a public flight of the electric flying car XPENG X2 at an event at the Dubai World Trade Centre. The zero-emission vehicle is a two seater car that uses vertical lift-off and landing (EVTOL) to transition from road travel to air.

Designed specifically for the complexities of urban driving, the X2 flies at low altitudes and can be driven manually or autonomously.

XPILOT is the company’s advanced driver assistance system. It provides guided options specifically for city or highway driving, including intelligent cruise, on- and off-ramp assistance, and speed limit adjustments. The car is made from carbon fibre in order to reduce the weight for flying.

In the future, the XPENG X2 will be suitable for low-altitude city flights, particularly over short distances. Medical transportation and sightseeing are therefore two promising potential applications for the technology. Supported in its exhibition flight by the Dubai Civil Aviation Authority, the success of the recent trip shines a light on the need for regulatory bodies to keep pace with technological developments.

Oil-eating, hydrogen-producing bacteria

Image: Cemvita

One major stumbling block to the adoption of hydrogen power is the fact that most hydrogen is currently produced from fossil fuel sources, with around 6% of global natural gas going to hydrogen production in 2019.

US startup Cemvita Factory has, therefore, turned to special microbes to generate hydrogen from depleted and abandoned oil and gas wells. The company’s process uses naturally occurring micro-organisms that consume the carbon in the gas and oil and release hydrogen – generating up to 20-50 tonnes of what it terms ‘gold’ hydrogen per field. Cemvita defines gold hydrogen as “the biological production of hydrogen in the subsurface through the consumption of trapped or abandoned resources”.

Cemvita claims that its researchers have been able to increase the performance of the microbes by six-and-a-half times their natural rate – enough to produce hydrogen at a cost of $1 per kg. This is thought to be a key cost target needed to advance toward commercialisation, given that fossil hydrogen is currently by far the cheapest variety.

Greener steel production

Image: H2 Green Steel

We’re staying on hydrogen for this next story and looking at its potential for decarbonising heavy industry.

Sweden’s H2 Green Steel company is building a greenfield steel mill in Boden in the north of the country, where the company plans to power steel production with renewable energy and green hydrogen. The company’s steel production process will emit 95% fewer emissions than current methods, it claims.

The electrolyser needed to produce industrial volumes of green hydrogen will be giga-scale and capable of creating enough of the gas to produce five million tonnes of steel annually. The plans are for the plant to be operational at that level by 2030.

As production at the mill scales up, subsequent housing, recreation, and local government development will benefit from mill waste products in the form of recycled energy and power resources. Having recently closed a Series B round of funding that raised €260m, the company will continue its build of the mill and implementation of its hydrogen and steel production processes.

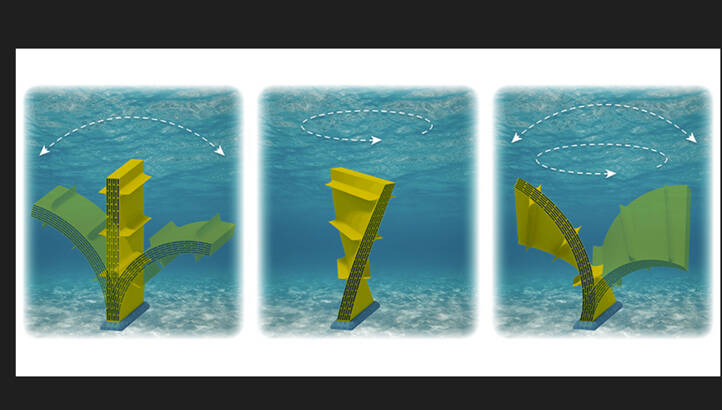

Generating electricity from waves, building, cars and even clothes

Image: Besiki Kazaishvili, NREL

Most devices that use ocean energy to generate electricity or other forms of usable energy rely on a single, large generator. This centralised approach has several disadvantages, including the need for expensive infrastructure and the risk of catastrophic failure. DEEC-Tec, by contrast, is a distributed embedded energy converter technology that uses many small, flexible converters instead of a single large one.

DEEC-Tec is based on the principle of piezoelectricity – the ability of certain materials to generate an electric charge in response to applied mechanical stress. The technology is still in the early stages of development, but it holds promise for revolutionising the way we harvest and use energy. The first patent for DEEC-Tec was for applications in marine renewable energy to harvest energy from ocean waves. The structures, known as flexWECs, are designed to dynamically deform in the presence of wave energy, allowing them to convert the energy into electricity.

This approach has several advantages. First, it is much less expensive to build and maintain than traditional generators. Second, it is much more difficult for accumulating ocean wave forces to damage all of the converters simultaneously, as the power is not concentrated on a single converter. Finally, DEEC-Tec can be used to harness energy from a variety of ocean locations and wave energy frequencies.

Beyond marine applications, the same technology could be used in the future to generate energy from the friction created by moving cars, the vibrations of buildings in the wind, and the movement of clothing.

A fresh(water) look at energy generation

Stock image, Urdaibai estuary, Spain

While hydropower, wind, and solar are already well-established forms of clean energy, another emerging energy source takes advantage of the different salinity levels of salt and fresh water. Bio-based materials on a nanoscale can be used to harvest the energy that is produced when freshwater empties into the sea at river mouths. French energy company Sweetch Energy has developed ‘INOD technology’ that is making this possibility a reality. And best of all? As long as the river flows steadily, the energy supply will be steady.

Called osmotic energy, such steadiness and abundance is relatively rare among renewables, making the solution a reliable source of power for communities on the coast and beyond. Sweetch Energy’s proprietary electrode systems combined with nanoscale membranes minimises energy loss during conversion and transportation.

As any A-level science student will know, osmosis is a process where water moves from a dilute to a concentrated solution across a semipermeable membrane. In osmotic energy systems the increase in pressure on one side of the membrane is used to generate energy. Osmotic power was first proposed in the 1970s, but membrane technology at the time was not sufficiently advanced to make it cost-effective. In the 2000s, Norwegian state-owned energy company Statkraft experimented with the technology, opening a prototype facility, but this programme was discontinued in 2013. Now, Sweetch’s nano-scale membranes could be the breakthrough that finally makes osmotic power a practical energy source.

Bladeless wind turbines for 24/7 generation

Image: Aeromine Technologies

As we’ve touched on above, wind suffers from variability as an energy source. A small, sleek wind turbine that generates power from winds as low as five miles per hour could tackle this issue and be one of the swiftest ways for buildings to become carbon-neutral.

Created by Aeromine Technologies, the bladeless turbines take up a fraction of the footprint of traditional wind farms and produce the same amount of power as that of 16 solar panels.

Designed specifically for use on top of large buildings with flat roofs, the turbines are easy to install and maintain, particularly because they do not have rotor blades. The turbines connect directly to a building’s electrical system and work much like a racing car does, using aerodynamic designs to amplify the flow of air away from the structure. Despite working constantly, the turbines are completely silent.

Aeromine generally installs 20 to 40 turbines on the side of a building’s roof that receives the most consistent wind. That is usually enough to provide all of the power required by a large commercial or residential building.

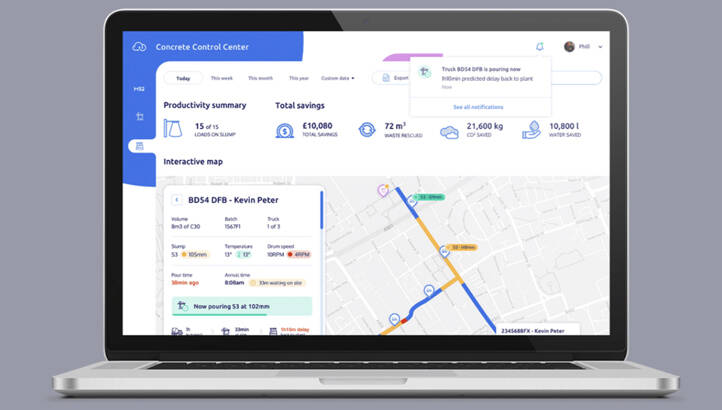

Digital transition in the concrete sector

Image: Cloud Cycle

It is estimated that the concrete industry is responsible for around 8% of all global carbon emissions. This is because the entire process of concrete production, distribution and use is highly energy intensive. At the same time, concrete, and its chief component, cement, are vital for almost all types of construction. Better managing the production and delivery of cement is the core idea behind startup Cloud Cycle.

Cloud Cycle uses sensors to monitor fresh ready-mix concrete in the truck, which allows construction companies to identify any issues early and enables the concrete to be delivered in the most efficient way possible. This approach avoids rejected batches and any associated waste. Sensors are housed in the CloudBox, which contains interfaces designed to mesh with current and future ready-mix concrete trucks. The device is also capable of running sophisticated machine learning algorithms.

Although only two years old, Cloud Cycle claims that it is receiving positive feedback and is actively working on funding and patent applications.

Springwise is the leading global innovation intelligence platform for positive and sustainable change. For the last 20 years, it has been uncovering and curating the most innovative thinking and ideas on the planet. Today, with a library of more than 11,000 global innovations, Springwise is trusted by thought-leaders, entrepreneurs, investors, educators, and tech disruptors as the leading source of inspirational ideas that matter. Visit Springwise.com

Please login or Register to leave a comment.