Register for free and continue reading

Join our growing army of changemakers and get unlimited access to our premium content

Transport is top-of-mind for many in August – the peak of summer holiday season. But one mode of transport that rarely features in most people’s daily lives is shipping. The majority of the world’s ships are used to move not people, but heavy cargo, and the sector remains heavily dependent on fossil fuels. Alternative fuels like ammonia and methanol are on the cards, but, in the meantime, our first innovation of the month is turning to wind power to decarbonise maritime operations.

If you did go on holiday by car, then you’re more likely than ever to have gone in an electric vehicle (EV). The energy density of EV batteries has plateaued for a while now, but our second innovation of the month looks set to reverse that trend, with a new type of anode that could pave the way for EVs with greater range.

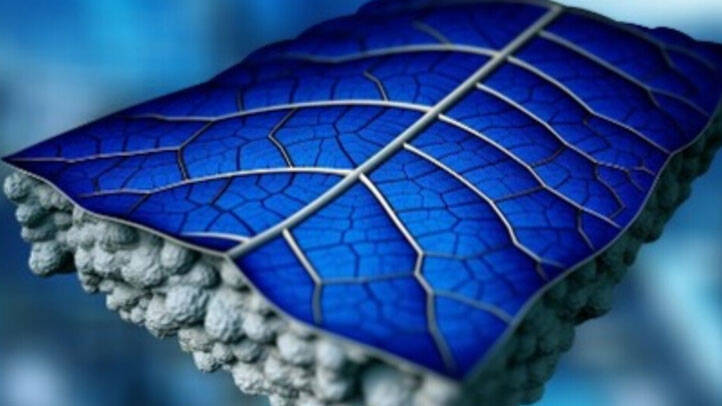

Like batteries, the cost of solar PV has come down dramatically over the past 10 years. But now, in our third innovation, researchers are mimicking the design of leaves to make solar PV even more efficient.

When we’re on the move during holiday season, we often pick up food on the go. Paper food packaging might seam more sustainable than plastic, but often it is laced with unrecyclable components, such as plastic coatings. Our fourth innovation of the month provides a bio-based alternative.

Meanwhile, the end of August is often a time when people discard their used holiday clothes, which often end up in landfill. Our fifth innovation is a way to turn these discarded clothes into useful materials.

And finally, extreme hot weather this year has highlighted the deadly issue of water scarcity. Our final innovation is a system that uses industrial waste heat to pull water from the air.

Cargill-backed boats with rigid sails

Image: Cargill

Shipping is a difficult sector to decarbonise, with more 99% of total energy demand for international shipping traditionally coming from oil. But now, innovators in the space are going back to the future by leveraging a new generation of wind propulsion technology to reduce fossil fuel consumption and emissions from shipping.

A key milestone for this avenue of innovation was passed this month, when Mitsubishi Corporation’s Pyxis Ocean, which was chartered by Cargill, set sail for its maiden voyage. The ship, is the first to be retrofitted with two ‘WindWings’ – large rigid wing sails measuring up to 37.5 metres in height that are designed to be fitted to the deck of cargo ships.

Produced for this project by Yara Marine Technologies, the WindWings are expected to generate average fuel savings of 30% if fitted on a new-build ship – which is not the case with the Pyxis Ocean, which is a retrofit. However, a key goal of the WindWings project, which has the backing of the European Union, is to provide a solution to reduce emissions from existing vessels given that 55% of the world’s bunker fleets are nine years old or older.

In the future, the WindWings could be combined with alternative fuels, such as ammonia or methanol, to unlock even more carbon savings.

High-tech anodes for next-gen EV batteries

Image: NanoGraf

Lithium-ion (Li-ion) batteries are ubiquitous, powering everything from portable consumer electronics to electric vehicles (EVs). But, while Li-ion batteries boast energy densities much higher than lead-acid batteries, increases in their energy density are plateauing. However, a new type of anode, produced by NanoGraf Technologies, may change this.

NanoGraf, a spinout from Northwestern University and Argonne National Laboratory, has developed a way to vastly improve the energy density of Li-ion batteries by replacing the conventional graphite-based anode with one based on a proprietary, doped silicon alloy with a protective inorganic and organic coating. The combination helps stabilise the material during charge and discharge.

While conventional graphite-based anodes offer a capacity of around 372 milliampere-hours per gram of mass (mAh/g), the NanoGraf material can achieve capacities as high as 1,400 mAh/g. This is a potential game-changer in battery manufacture, allowing longer-lasting, higher-energy, and higher-power Li-ion batteries. In addition, the new anode can be easily dropped into existing battery manufacturing processes.

A bio-inspired solar power leaf

Image: Dr Gan Huang

Photovoltaic (PV) solar panels convert the sun’s energy into electricity. Between 2009 and 2019, their price fell by 89^%, and now a research team at Imperial College London has turned to nature for inspiration to make them even cheaper.

The new PV leaf is made using low-cost materials, and experiments have shown that it generates more than 10% more electricity than conventional solar panels.

Key to the design’s success is its mimicry of the transpiration processes exhibited by natural leaves to efficiently remove heat from the PV cells. The PV leaf uses hydrogels to simulate sponge cells and natural fibres that cushion leaf vein bundles.

These cooling techniques, eliminate the need for control units, fans, pumps and effective porous materials. The PV leaf is also adaptable to outside temperatures and solar conditions and is able to produce additional freshwater and thermal energy.

A biodegradable coating for paper packaging

Image: Melodea

Paper is often hailed as the perfect sustainable alternative to plastic packaging, with many consumers instinctively putting paper materials in their recycling bins without thinking. However, many paper-based products are laced with unrecyclable components, such as plastic coatings.

Israeli startup Melodea has a solution – bio-based coatings that protect against water vapour, oil and oxygen. Made from wood pulp and waste side streams from the paper industry, these fully plant-based coating solutions are completely recyclable, compostable, and biodegradable. They are suitable for use on paper, paperboard, PET plastic, and bioplastic products, and are also completely non-toxic and FDA-compliant.

Instead of absorbing water and disintegrating, or soaking up grease and becoming unrecyclable, the coatings act as barriers to keep the paper clean and dry. Melodea’s ‘VBcoat’ product resists both water and grease, as does its ‘VBseal’ coating, with the latter also providing heat-sealability to close up the packaging.

These can be used on their own or combined with the company’s ‘MelOx’ product to provide an additional oxygen barrier. Until now, most food packaging has relied on unsustainable materials like plastic because it stops the transmission of air, keeping produce inside fresher for longer.

Because Melodea’s solutions can be applied using standard coating technologies, they can be scaled easily and quickly. The could have applications in sectors such as cleaning products and cosmetics as well as food and drink.

Turning used clothes into bioethanol and cellulose

The Ellen MacArthur Foundation estimates that less than 2% of the 100 billion garments made each year will be recycled into new textile products. Recycling in other ways is also uncommon; the vast majority of used clothes end up as waste.

However, one startup is offering a new approach to textile waste. The Berlin-based female co-founded company, Re-Fresh Global, is turning discarded clothing into new raw materials. These materials can be used to create products like cosmetics, cars, packaging, pharmaceuticals, fibres and furniture.

First, the company uses its automated technology to sort and separate textile waste, depending on its material composition and colour. Then, Re-fresh’s patented biotechnology transforms shredded textile fibres into industrial quantities of new and highly versatile resources.

This process creates three new raw material types: nanocellulose, ethanol, and sanitised textile pulp. The nanocellulose is strong and highly versatile, meaning it can be used in items including packaging, paper, and pharmaceuticals. The pure bioethanol (alcohol) has various useful applications across the beauty, sanitation, and biofuel industries. And finally, the textile pulp, made from recycled natural and synthetic fibres, can be used in the production of new fibres, whether that be for car upholstery or sound-absorbing workplace interiors.

New technology to harvest water from the air

It was recently World Water Week, which highlighted how there are many places in the world where clean water is not readily available. While multiple factors like inadequate or damaged infrastructure, poor resource management, and pollution are contributing to low water supply, climate change is also playing a part.

This is where NovNat Tech comes in. With its technology, NovNat aims to improve water security and boost climate change resilience. This Birmingham-based company has developed a novel ‘atmospheric water harvester’ powered by waste heat from industrial operations, to help provide reliable and consistent water access by extracting water from the air at scale. NovNat’s proprietary porous materials act as a nano-scale selective sponge to soak atmospheric humidity and convert it into water.

Having been rigorously tested, the harvester’s materials have demonstrated breakthrough performance in capturing and releasing water from the air – much faster and with less energy required than pre-existing atmospheric water generation (AWG) systems. The company is currently developing a prototype AWG system, funded by Innovate UK, designed to deliver water on the go for rescue and military vehicles.

Springwise is edie’s innovation content partner. It is the global innovation intelligence platform for positive and sustainable change. With a growing database of 11,000+ innovations, Springwise is the place of record for innovation that matters. Springwise.com.

Please login or Register to leave a comment.