Register for free and continue reading

Join our growing army of changemakers and get unlimited access to our premium content

This month marked the fifth annual edition of edie’s Net-Zero November, which aims to inspire and empower sustainability and energy professionals on the road to a net-zero carbon future for business.

Although we have many of the technologies we need to transition to a net-zero world (onshore wind and solar power are now cheaper than fossil fuels in many parts of the world, for example), innovation remains extremely important in facilitating the transition to a decarbonised economy. In particular, with much of the low-hanging fruit already plucked, there is a need to double down on innovation in the most hard-to-abate sectors of the economy.

Generating clean industrial heat is one of the more challenging problems we face, and our first innovation this month uses thermal batteries to allow heat from solar arrays to be delivered to manufacturers when its needed. Heat is also a challenge for the residential sector, with most UK homes still reliant on gas boilers. A new thermal ‘battery,’ developed in the US, optimises air-source heat pumps by storing energy as hot water when it is most cost-effective, efficient, and environmentally friendly to do so. Another technology for green heating is geothermal energy, and a US company is making this a more viable option for tall urban buildings by using automated drilling technology.

Beyond heat, we need to be able to store energy to maintain security as more intermittent renewables come online. In our fourth innovation, a UK startup is repurposing electric vehicle batteries to create smart energy storage systems at the ‘grid edge’.

Green hydrogen is another key part of a future net-zero economy, but further innovation is needed to bring its costs down. Our penultimate innovation this month is, therefore, a technology to speed up R&D cycles for electrolysers – the key piece of hardware in green hydrogen production.

And finally, it is crucial to ensure that the resources needed for the energy transition do not create their own environmental problems and geopolitical tensions. Magnets are used in many of the technologies needed for net zero, and a lot of these are made from rare earths that are associated with these problems. Our sixth and final story this month concerns a company that has developed clean energy magnets made from abundant materials.

Volcanic batteries for industrial process heat

Heat is crucial for many manufacturing processes, yet the generation of that heat is often emissions-intensive, with industry responsible for 30% of all of the UK’s heating-related greenhouse gas emissions. Renewable electricity is not always an option due to high energy demands and a need for consistent supply. To solve this problem, British startup Caldera has developed a new type of heat storage system.

Caldera’s system pairs with a solar array of almost any size, with the solar power stored as heat using novel storage cells made of an aluminium-volcanic rock composite encased in vacuum insulation. These highly efficient modular cells are rapidly heated to 500 degrees Celsius and can store this energy for hours, ready to deliver heat on demand at temperatures between 80 to 200 degrees Celsius, which is the temperature range needed for many industrial processes.

The cells can deliver heat whenever required, allowing businesses to substitute expensive, and non-renewable, gas and grid electricity for cheap on-site solar power.

Caldera’s initial target market is factories that use industrial steam, which encompasses more than a third of all UK industrial energy use. If successful, this system, and one’s like it, could go a long way in getting the UK to net-zero.

Electric thermal heating systems

California-based Harvest Thermal has created a smart, all-electric thermal battery system that could contribute to the phase-out of fossil fuel heating for homes.

Under the Harvest Thermal system, air-source heat pumps pull warm air into a building to heat water in a storage tank. A ‘Harvest Pod’ tracks the price of electricity and ensures that the water in this storage tank is fully heated when electricity costs are lowest (and least polluting), which is generally in the middle of the day. Using the heat pump at the warmest time of day also ensures the highest levels of efficiency in the running of the device.

The system replaces traditional gas furnaces and hot water heaters and, in doing so, reduces a building’s carbon emissions by up to 90%. The smart system integrates with the piping of existing HVAC systems, and the Pod connects wirelessly to the cloud to provide its analysis of prices and tracking of heating and water use.

Geothermal energy to serve tall buildings

Geothermal energy is one of the most energy-efficient methods for providing HVAC for businesses and communities alike. But the problem that has traditionally faced geothermal power is the high upfront cost of establishing boreholes to tap into this energy in the ground. And for tall commercial properties or apartment blocks, traditional geothermal systems have also not been able to provide enough energy to heat or power the entire building. This is where US startup Bedrock Energy comes in.

The company has developed new autonomous drilling and subsurface modelling technology that allows bore field construction to be around three times quicker and cheaper. Crucially, unlike existing boreholes, which are often drilled 300 to 800 feet below the Earth’s surface, Bedrock drills 2,000 feet underground where the temperatures are much hotter.

Because of this, the company reduces the number of boreholes required for a project – from 28 to eight in some cases – meaning tall commercial buildings with limited land space can still make use of this abundant energy source for their heating and cooling systems.

Using its advanced algorithms, Bedrock can accurately predict the energy transfer to buildings from the geothermal site. The company then specially designs a project’s geothermal loop field to optimise borehole locations for the best long-term energy returns.

Circular battery systems for homes and businesses

As already mentioned, as the grid transitions to variable renewable energy sources like solar and wind, there is a growing need for energy storage to smooth out peaks and troughs in generation. But questions are already being asked about how to grow storage capacity without over-exploiting raw materials for batteries.

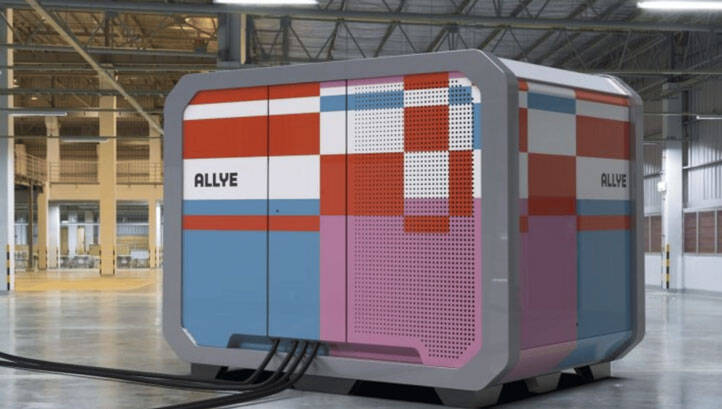

To meet this challenge, UK startup Allye has developed distributed energy storage at the grid edge by creating energy storage systems that use second-life electric vehicle (EV) batteries. These modular systems are flexible and managed via the cloud, with technology, including digital twins, machine learning, and artificial intelligence (AI) that optimises behaviour and performance.

Allye’s cofounder and CEO Jonathan Carrier told Springwise that the company delivers energy storage “that is two times cheaper and with 60%lower embedded CO2 than comparable systems by repurposing EV batteries.”

A key differentiator for Allye is the fact that it repurposes whole battery packs intact, including the battery management system, cooling, and cables. By combining several of these battery packs, the startup creates its innovative energy storage system, dubbed the Max, which can even combine two different lithium-ion battery chemistries.

Carrier added that Allye will be installing its first system with a customer shortly and is hoping to start series production in the second quarter of 2024.

Speeding up R&D for green hydrogen

Hydrogen is a clean fuel and feedstock that many experts believe will be key to decarbonising industries like trucking and steel production. But to be a truly sustainable solution, it needs to be produced without generating large quantities of carbon emissions.

We already know how to produce low-emission ‘green’ hydrogen by running a renewable electric current through water (H2O) to separate the hydrogen and oxygen atoms. However, the core piece of hardware needed for this process – known as an electrolyser – is currently expensive, which means that just 1% of the world’s hydrogen is produced with renewable energy. Bringing down the cost of electrolysers will require continuing research and development, and New Zealand-based startup Bspkl is facilitating this process.

Proton exchange membrane (PEM) electrolysers are one of the two dominant technologies for green hydrogen production today. And at the core of PEM electrolysers are catalyst coated membranes (CCMs) – components that play a key role in separating the hydrogen and oxygen atoms in water molecules. These CCMs are made up of catalysts – materials that speed up a chemical reaction – applied to a solid membrane. Bspkl has developed a proprietary manufacturing process that enables rapid sampling and testing of innovative CCMs.

Using technology pioneered in the semiconductor industry, the startup produces CCMs using up to 25 times less catalyst material than existing processes. The CCMs produced are also durable yet flexible, which means that the catalyst layer doesn’t easily crack or gradually peel away from the membrane. Both the catalyst and the membrane in a CCM vary depending on the type of battery and the precise performance needs of the manufacturer. Bspkl’s process is agnostic, which means it can be used with a range of catalysts and membrane materials.

Perhaps the most important benefit of the startup’s technology is that it enables fast prototyping of new designs, being able to produce and test new CCM samples in a day. This, in turn, speeds up research and development cycles and enables manufacturers partnering with the company to develop new catalyst and CCM products and deliver them to market in a matter of weeks or months, rather than years.

Today, Bspkl is capable of small-scale production, but its process is specifically designed to easily scale up as demand for CCMs grows.

Magnets free from rare earths

Magnets made from rare earths have become ubiquitous in several high-performance technologies and products ranging from wind turbines and EVs to consumer electronics and robots. However, while rare earth elements are essential for critical infrastructure, China controls the bulk of the supply chain, making the magnets subject to geopolitical tensions.

Now, Niron Magnetics has developed a high-performance permanent magnet that is as strong as a rare earth magnet but does not use any rare earth elements. Instead, the company’s ‘Clean Earth Magnet’ is produced using abundant and easily recyclable materials (iron and nitrogen).

Not only do Niron’s magnets exceed the performance of rare-earth-based equivalents by up to 50%, according to the company, but they also have a 75% lower overall environmental impact. Additionally, the Clean Earth Magnet is stable over a wide range of temperatures and, helped by the company’s scalable manufacturing processes, can be produced at a lower cost than those made from rare earths.

Niron’s magnets were recently selected as one of TIME Magazine’s Best Inventions of 2023, and TIME is not the only one excited by this technology. The company has forged commercial partnerships with companies like Volvo Cars, General Motors, Tymphany, and Western Digital.

Springwise is the global innovation platform for leaders looking to drive positive and sustainable change. Our weekly newsletter is a round-up of our most popular innovations and our latest features. It’s free to access and you can sign up here.

Please login or Register to leave a comment.