Register for free and continue reading

Join our growing army of changemakers and get unlimited access to our premium content

These innovations could help decarbonise sectors including energy and the built environment

Innovation will be key to delivering on the world’s net-zero targets, and this is particularly true in hard-to-decarbonise sectors that don’t always grab the headlines. Many of the hidden building blocks of our daily lives fall into this category, and two of this month’s innovations are tackling the sometimes-overlooked emissions associated with everyday chemical products – from cleaning wipes and surface sprays to paints and car parts.

But innovation is also important in more visible and established technologies like solar power. So, we’re also highlighting new type of solar roof shingle that is making it even more attractive for homeowners to make the switch to carbon-free energy.

Moving from domestic to commercial buildings, we have spotted a new design for ‘bladeless’ wind turbines that can provide near-constant power, harvesting winds as low as five miles per hour. And for commercial real estate portfolios as a whole, an AI-based solution is developing decarbonisation plans in only a fraction of the time it would take a human expert.

Finally, we turn towards a potential solution for methane in the agriculture sector. New containerised biogas plants are preventing methane emissions from livestock manure, while also generating green hydrogen and biomethane that can directly replace fossil fuels.

Read on for our innovations showcase for edie’s Net-Zero November, powered by edie’s innovation partner Springwise.

Carbon-negative chemicals for everyday life

Synthetic biology is a new branch of biology that uses a combination of genetic engineering, biochemistry, and molecular biology to create new artificial biological systems and organisms. In addition to revolutionising genetic engineering, synthetic biology is also helping to reduce carbon emissions. Startup Solugen Bio is one of the companies utilising synthetic biology, in this case, to manufacture chemical-based products using bio-based feedstock instead of fossil fuels.

Solugen Bio uses artificial intelligence (AI) to engineer enzymes and metal catalysts that, in turn, allow the production of molecules at room temperature using bio-based feedstocks, with no toxins and no waste. The company’s ‘Bioforge’ uses feedstocks composed of corn syrup and deionized water. This is pumped into the enzyme reactor, where specially engineered enzymes convert the feedstock to the desired molecules. This produces an ‘intermediate product’ which is then mixed with compressed air and flowed over the company’s engineered metal catalysts. This transforms the compound again into the final product.

The entire process is powered by wind-generated electricity, which the company claims is 10 times more efficient than creating steam by burning natural gas. Solugen Bio has a wide range of everyday applications, from cleaning wipes and surface sprays to food additives.

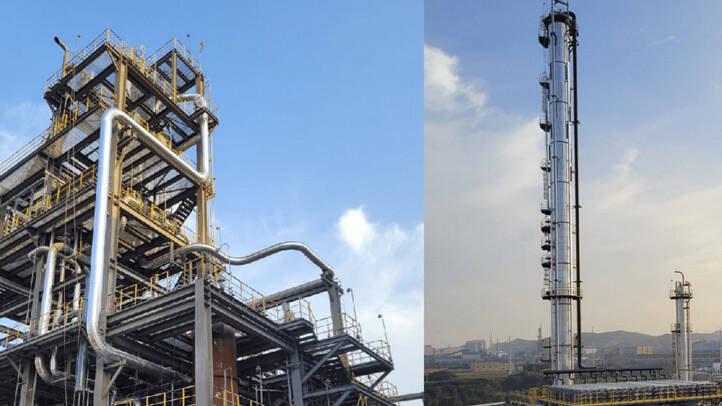

The world’s first commercial CO2 to methanol conversion plant

Image: Carbon Recycling International

Methanol (CH3OH) is a chemical building block used in hundreds of everyday products, including plastics, paints and car parts. It is also a clean-burning fuel but methanol production itself is not clean – it is produced in an energy-intensive process that usually begins with natural gas: a fossil fuel. Now, Carbon Recycling International (CRI) is working on a way to change this with a production process that uses captured waste carbon dioxide and hydrogen gases.

CRI has recently completed the world’s first commercial-scale CO2-to-methanol plant, located in Henan Province, China. The cutting-edge facility uses Emissions-to-Liquids (ETL) technology developed by CRI and first demonstrated at its pilot plant in Iceland.

The company’s process uses carbon dioxide that is recovered from existing lime production emissions, and hydrogen recovered from coke-oven gas. The waste gases are captured at their point of emission and transferred to the gas conditioning system, where impurities are then removed to produce carbon dioxide. At the same time, hydrogen is generated by water electrolysis using a renewable electricity source.

Solar shingle roofs

Image: GAF Energy

Aside from the cost, one of the biggest factors slowing the uptake of solar panels on domestic properties is the way the panels look. Realising this, several manufacturers have developed photovoltaic roof tiles – solar tiles that can look like standard tiles. However, GAF Energy is the first to develop solar tiles that can also be installed the same way as their non-solar counterparts.

The GAF Timberline Solar shingles can be nailed down in packs, just like the everyday shingles used on normal, non-solar roofs. This means that it takes days instead of weeks to install a GAF solar roof. The shingles are made of a sandwich of glass, polysilicon solar cells, and a top layer of fluorinated alkane ethylene polymer. They are fire and impact-resistant and can even be walked on.

GAF’s nailable tiles are much cheaper than many alternatives, and about half the cost of the Tesla Solar Roof. It takes around 400 square feet of the tiles to supply a six-kilowatt system – about the same amount of space as a rack-mounted solar panel system. The rest of the roof can then be filled in with normal GAF shingles designed to match the solar shingles.

Bladeless wind turbines suitable for cities

Image: Aeromine Technologies

Just like sunshine, wind is a fairly constant aspect of the weather, yet as an energy source, it still suffers from variability. Now, a small, sleek wind turbine that generates power from winds as low as five miles per hour could tackle this issue and be one of the swiftest ways for buildings to become carbon-neutral. Created by Aeromine Technologies, the bladeless turbines take up a fraction of the footprint of traditional wind farms and produce the same amount of power as 16 solar panels.

Designed specifically for use on top of large buildings with flat roofs, the turbines are easy to install and maintain, particularly because they do not have rotor blades. The turbines connect directly to a building’s electrical system and, despite working constantly, are silent.

Aeromine generally installs 20 to 40 turbines on the side of a building’s roof that receives the most consistent wind. That is usually enough to provide all of the power required by a large commercial or residential building. When combined with solar, a building could certainly run completely on renewable energy.

AI-powered net-zero real estate plans

Canadian property technology experts at Audette have built an artificial intelligence (AI) platform that does in a few hours what it would ordinarily take humans years to do – analyse a full portfolio of commercial real estate for decarbonisation opportunities. The AI builds a plan to retrofit every building in a portfolio in the most cost-efficient manner.

From renewable energy opportunities to carbon-negative materials, Audette can build a carbon transition plan for any building. The platform layers operational data with capital planning and a breakdown of costs and energy usage of each piece of equipment and location, as well as forecasts of emissions. This allows for effective, efficient retrofitting and long-term planning for a carbon-negative future.

The platform recognises and suggests methods for maximising efficiencies across an entire business, not just a single building.

Next-gen biogas plants

Image: Reverion

German energy company Reverion is scaling renewable energy production while creating green hydrogen and capturing carbon – all in the same micropower plant. The company’s power plants are built into shipping containers for ease of use and utilise high-temperature fuel cells, rather than combustion engines. The fuel cells run on biogas, which comes from animal manure, making it a weather-independent renewable energy source.

By removing manure from the land, the plants reduce global methane emissions. And by eliminating the need for fossil fuel, emissions drop further. Biogas is used to create biomethane, a fuel source capable of directly replacing fossil fuels. It can be pumped into existing infrastructure, requiring no new parts or systems. Each unit produces a standard 100 kilowatts of energy and can be used in bundles for large facilities.

Upgrading the biogas to biomethane produces carbon dioxide, another useful resource. The captured CO2 can be stored or used as an ingredient in a range of chemical production processes. Reverion stores it under the sea or sells it for industrial use. And when the plants produce more energy than is required, the system reverses and begins making and storing green hydrogen.

Springwise is the leading global innovation intelligence platform for positive and sustainable change. For the last 20 years, it has been uncovering and curating the most innovative thinking and ideas on the planet. Today, with a library of more than 11,000 global innovations, Springwise is trusted by thought-leaders, entrepreneurs, investors, educators, and tech disruptors as the leading source of inspirational ideas that matter. Visit Springwise.com

Please try and interpret US corporate press releases a little more intelligently! The GAF solar system is not “the first to develop solar tiles that can also be installed the same way as their non-solar counterparts” – there have been several similar systems available in the UK (eg from Marley) over the years, and the 6kWp output figure is not appropriate in the UK (as it would be too large for a domestic grid connection).

I also have doubts about the Aeromine item – this is a Texas based company with a solution that looks very similar to ones that were widely tested in the UK, but failed to generate meaningful amounts of energy on real buildings. It would be good if they have solved the physics, and obviously higher costs of substituted energy will help the economics, bot I’m not sure…

Finally, the Chinese methanol one is interesting, but most of the hydrogen seems to come from a coking coal, which is a very grey form of hydrogen!

I’m sorry, but I would expect higher editorial standards from edie.