Register for free and continue reading

Join our growing army of changemakers and get unlimited access to our premium content

It is increasingly widely understood that in nature there is no such thing as waste – the materials left over from one biological process form the key ingredients of another. And our first four innovations this month show that this can also be true for our human economy.

In 2022, the world produced 4.1 billion tonnes of concrete and 68.4 million tonnes of aluminium. In our first innovation, surplus concrete is used to capture carbon while boosting the health of farmland, while in our second, scrap aluminium is reimagined as a means of transporting renewable energy to where it’s needed most.

Meanwhile, we produce around 400 million tonnes of plastic waste each year. Rather than choking the world’s oceans, our third innovation shows that waste plastic could be used to create useful new fuels and materals.

One source of waste that is on the rise is the waste from electric vehicle batteries, and our fourth innovation is simplifying the recycling process for battery cathodes.

Beyond waste, our final two innovations look at food production, which some researchers estimate to be responsible for as much as one-third of all man-made greenhouse gas emissions. Cultivated meat grown in a lab could one day be a regular fixture on our dinner plates. But it could also be in our pets’ bowls, and our penultimate innovation is using machine learning and AI to help make this happen.

Finally, palm oil is in a huge proportion of the food we eat – and much else besides. Our final innovation is a potential alternative to the ubiquitous material.

Concrete-based carbon capture

Stock image

Enhanced weathering is a process in which carbon dioxide in the air reacts with fine rock particles spread over an area of land or sea. The technique accelerates natural chemical weathering processes and locks away CO2 by converting it into stable bicarbonate ions, which can be stored in the ocean for more than 80,000 years (if the process takes place on land, the bicarbonate makes its way into waterways that eventually wash it to the sea).The process has attracted the interest of scientists, and now Irish startup Silicate is conducting an important trial of the technology on farmland in the US corn belt.

The source of the rock particles influences the impact of enhanced weathering techniques and using waste materials removes the need for extractive and environmentally damaging mining. Silicate has therefore turned to surplus concrete, having developed a method of altering returned milled concrete to unlock its full carbon capturing capabilities. Around 10% of all the ready-mixed concrete produced in the US is returned to suppliers, so the startup’s process makes use of a common waste material.

Silicate has conducted promising trials in Ireland, but the latest trial – which is being conducted on 50 hectares of land in Buckingham, Illinois – is testing how the concrete material performs in the soil conditions of the American Midwest. Enhanced weathering offers co-benefits for farmland such as increased soil health and crop productivity, so its application in one of the world’s most important agricultural regions could have benefits beyond capturing carbon. A successful result would also pave the way for the rapid scale-up of the process through collaboration with farmers and companies across the Midwest.

If successful, Silicate estimates that for every tonne of concrete applied to soil in the Midwest, 200 kilogrammes of CO2 will be removed from the atmosphere permanently. Independent research has also found that enhanced weathering compares favourably to other carbon dioxide removal strategies, such as direct air capture and bioenergy with carbon capture and storage, in terms of land use and energy and water intensity.

A new way to store and move clean energy

Stock image

How can we get clean energy to where we need it? Today, solar and wind energy can be transported through power lines or stored and moved through electrochemical and thermal batteries. However, building transmission infrastructure can be challenging, and the latter two solutions are only suitable for short journeys or stationary storage.

Now, startup Found Energy has come up with an entirely novel method of energy transportation: aluminium energy storage packs. These are based on the idea of extracting energy from aluminium by accelerating the rusting process to produce heat and hydrogen.

All aluminium contains potential energy in its chemical bonds, and this energy primarily derives from the electricity used to smelt the metal. However, if left to its own devices, aluminium reacts with oxygen in the air forming a ‘protective’ oxide layer that locks away this potential energy.

Found Energy’s innovation is a catalyst that strips away the oxide layer making the aluminium reactive. The ‘activated’ aluminium can then be added to a reactor, which is then flooded with water. The water reacts with the metal, producing heat and hydrogen, which can be used directly in industrial processes or as a fuel respectively. After the reaction between the water and the aluminium takes place, the material left over is aluminium hydroxide, which is already used in cement, fire suppressants, pharmaceuticals, and, crucially, as the primary raw material in the production of new aluminium.

The aluminium used in Found Energy’s packs – which are light and can be easily transported to where energy is needed – is scrap that would otherwise be landfilled. What is more, the aluminium smelting process is already electrified, which means that, as the grid decarbonises, much of the energy stored in aluminium will become ‘green’, as it will have originally come from a renewable source.

Turning waste plastic into hydrogen

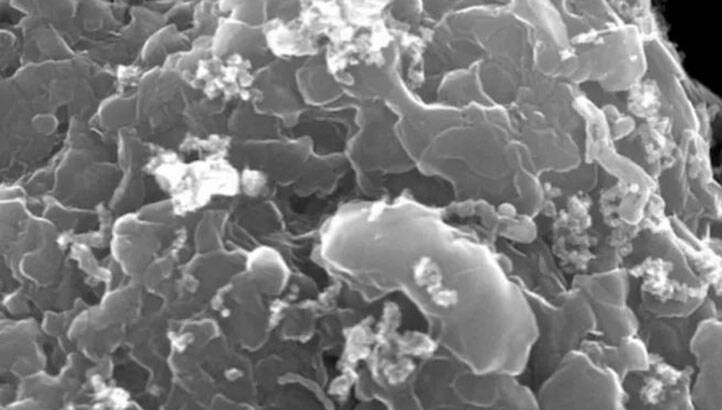

Image: Kevin Wyss/Tour Lab

Eradicating plastic pollution and producing hydrogen in a low-carbon process have both been the focus of countless researchers and innovators in recent years.

Now, researchers from Rice University believe they have found a way to combine both agendas, harvesting hydrogen from plastic waste without generating large volumes of carbon emissions.

The lab has been working with a process called flash Joule heating – where heat is produced when an electric current flows through a resistor – to achieve the ultrafast heating of plastics. The team realised that rapid heating could vaporise the hydrogen in plastics, leaving behind graphene – a pure carbon, super-valuable nanomaterial with a broad range of applications. Even if the graphene created in this process was sold at just 5% of its current market value, the team claims that the sale would completely cover the cost of the process.

Using flash Joule heating to upcycle waste plastics is highly efficient and requires no catalyst or other solvents. At the same time, the team was able to recover up to 68% of the vaporised hydrogen as gas, with a 94% purity. Because the process creates graphene as a valuable by-product that can be sold, the team highlights that the technique is significantly more affordable – and therefore scalable – than current green hydrogen production methods.

Low-impact EV battery recycling

Image: Nissan

The demand for battery recycling is expected to grow as the adoption of electric vehicles (EVs) accelerates. In fact, the global EV battery recycling market is set to grown from $2.3 billion in 2022 to $9.8 billion in 2028.

Now, researchers from the University of Birmingham have developed a new method of recycling the highest-value part of a car’s battery: the cathode.

The researchers used ascorbic acid (vitamin C) as a ‘leaching agent’ to extract low-value materials from cathode material taken from an old Nissan Leaf battery, leaving behind solid nickel and cobalt-based materials that can be directly recycled.

Today’s EV battery recycling approaches rely on dissolving battery cathodes using strong acids that leave behind hazardous waste. But the University of Birmingham team has now shown that it is possible to use less hazardous organic acids.

What is more, the team’s approach significantly simplifies the process, reducing the number of steps and costs involved, while also reducing the energy intensity of the process.

By conducting the test on an actual Nissan Leaf battery, the researchers are taking a real-world approach, focusing on what is actually going into battery recycling supply chains. The Nissan Leaf was the first electric vehicle to be produced for the mass market so its batteries will be among the first to be recycled.

AI to help advance cultivated meat production

Image: BioCraft

Cultivated meat is ‘real’ meat that is grown in the lab from animal cells. Today, the industry is in its infancy, and there remains uncertainty about its future trajectory. However, some commentators believe it could be signficant, with McKinsey forecasting that the global market will be worth $25bn by 2030.

Much of the focus has been on cultivated meat for human consumption. But Austrian startup BioCraft is focusing instead on the pet food market, and is doing so by deploying artificial intelligence (AI) and machine learning to tackle one of the key bottlenecks in the commercialisation of cultivated meat.

Today, the main pitfalls for cultivated meat innovators lie in the R&D process. BioCraft is learning about the biochemical machinery of anmal cells by using algorithms similar to those that have been deployed by the pharmaceutical industry to identify new drugs. The company’s tool collects and crunches data from scientific studies and databases to generate insights into potential nutrient inputs that can enhance biological processes essential to the production of cultivated meat.

By using its AI tool, BioCraft is reducing the number of lab experiments it needs to hone its products while avoiding expensive ingredients and those that may raise eyebrows among regulators.

The pet foods the startup is creating offer nutrients without hormones, steroids, antibiotics, or chemical contaminants. They are also less likely to carry dangerous food-borne pathogens. If cats and dogs formed their own nation, it would be the fifth-largest meat-eating country on earth. By speeding up the development of cultivated meat, BioCraft is hoping to reduce this impact.

A game-changing palm oil replacement

Image: Queen Margaret University

Palm oil is the most produced, consumed, and traded vegetable oil in the world. Because of its widespread cultivation in tropical regions, it is also a major cause of biodiversity loss. But palm oil is difficult to replace economically and at scale due to its yield, which is much higher than alternative vegetable oils.

Innovators worldwide are searching for particularly efficient ways to replace the oil in the myriad products it is used in – from lipsticks and chocolate to laundry detergent and animal feed.

Now, researchers from the Scottish Centre for Food Development and Innovation at Edinburgh’s Queen Margaret University may have found one of the most cost-effective options. Using a combination of rapeseed oil, fibres, and linseed industry by-products, the team of scientists have created PALM-ALT.

PALM-ALT has 88% less saturated and 25% less overall fat than palm oil and contains more fibre and protein. The alternative fat ingredient is also allergen-free and contains no additional flavours, colours or sweeteners.

The palm oil alternative has the consistency of mayonnaise, and particularly importantly, is made from products easily sourced in the EU and UK. With this new material, manufacturers have an opportunity to locally source their palm fat equivalent, thereby cutting down on transport-related greenhouse gas emissions while reducing pressure on communities living near rainforests.

The team has patented PALM-ALT and is exploring industry-level partnerships for the use of its palm oil replacement.

Springwise is the global innovation platform for leaders looking to drive positive and sustainable change. Our weekly newsletter is a round-up of our most popular innovations and our latest features. It’s free to access and you can sign up here.

Until such time that an alternative to palm oil can be proven to be economically and environmentally viable at large scale, the need to ensure sustainable production of palm oil remains paramount.