Register for free and continue reading

Join our growing army of changemakers and get unlimited access to our premium content

Fashion Revolution Week was founded in the wake of the Rana Plaza disaster in 2013. Held annually by NGO Fashion Revolution, it is an opportunity for mass advocacy for a global fashion industry that conserves and restores the environment and values people over growth and profit.

According to statistics published by the United Nations Environment Programme (UNEP) and the Ellen MacArthur Foundation, the fashion industry uses 93 billion cubic metres of water each year, and generates 10% of annual global carbon emissions. It is also a huge cause of waste, with a bin lorry of material and products ending up in incineration and landfill each second and half a million tonnes of plastic microfibres from synthetics entering the oceans each year.

Fashion systems, in their current form, exploit people as well as planet. Fashion Revolution claims that only 2% of fashion workers globally are paid a liveable salary.

Fortunately, there are many innovators who are rethinking fashion from all angles. Their solutions are often technical—finding alternative materials, processes, and technologies—or logistical. But behavioural change is also needed to encourage more circular thinking.

From black algae t-shirts, to a ‘Photoshop for textile design’, this article rounds up eight of the most promising innovations helping to deliver a fashion industry that resembles the one envisaged by Fashion Revolution Week.

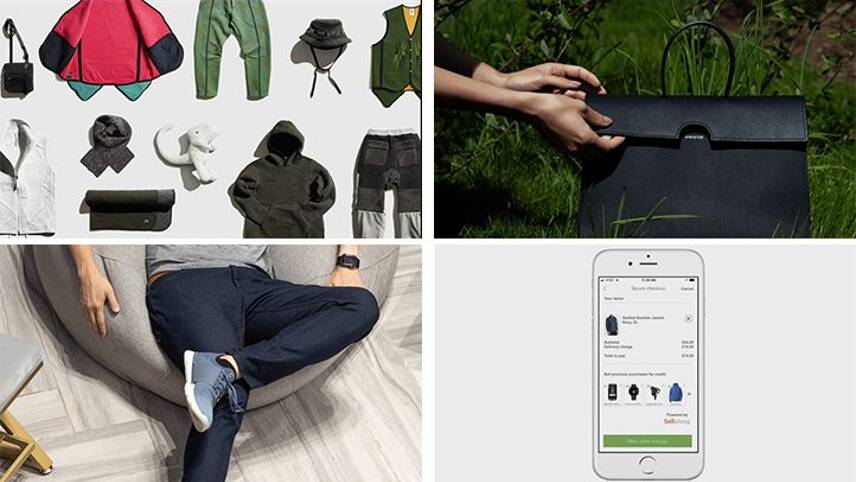

Made to measure – with a modern twist

Image: unspun

Fashion’s waste issue stems from the fact that the system is getting ever faster. Retailers are launching bigger collections, more frequently, and this growth is outpacing the scaling of resale and recycling systems. This leads to waste at all stages of the value chain, but especially at the consumer stage. One 2018 study found that 80% of British shoppers have purchased one or more fashion items, then binned them without wearing them even once.

Making products to custom requirements is a way to avoid overproduction and factory waste This method also ensures that the customer will not throw the items away quickly, either due to poor fit or to a lack of emotional durability.

Innovators pioneering made-to-measure for the 2020s include unspun, which uses 3D scanning and weaving to make denim, and Emperor’s Old Clothes, which makes unique garments using vintage fabrics. Platforms like eBay and Depop are also fast becoming go-to destinations for one-off custom pieces from independent sellers.

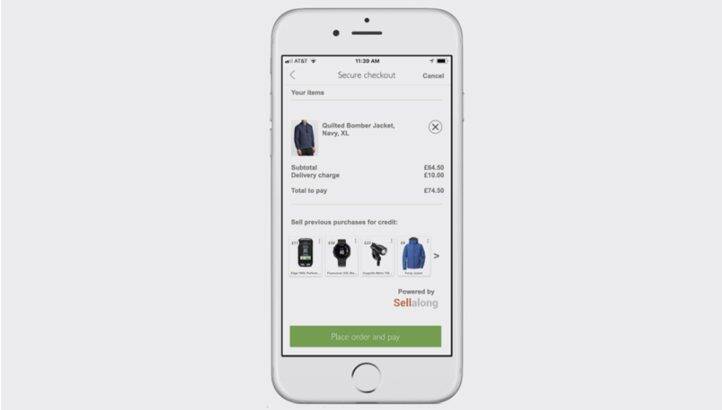

Clothing resale plug-ins

Image: Sellalong

Driven by a mission to make circularity a part of every purchase, UK startup Sellalong has developed software that makes it easy for consumers to re-sell their old clothes at the same time as they are shopping online for new ones.

The plugin, which can be integrated into the apps and websites of retailers, presents customers with their previous purchases at the point of checkout. Each item is attached with a specific sell-back price, which the customer receives in the form of credit.

Customers who decide to re-sell their old items receive a free shipping label alongside their new purchase. The company uses established resale platforms to sell the second-hand garments and sends the net proceeds to the retailer. Items that cannot be sold are responsibly recycled.

Digital luxury resale platforms

Image: myGemma

The idea of resale is nothing new in fashion – in 2020, the global market value of second-hand and resale apparel was estimated to be worth $27 bn. The majority of this value is not derived from the reale of luxury items, but rather from the resale of items from high-street names through charity shops, consignment stores and websites.

Several platforms are working to scale resale for luxury fashion, providing authentication, listing services and more. They include Vestiaire Collective and myGemma, the latter of which offers a ‘White Glove Service’ in which a dedicated team of VIP managers conduct free in-home appointments and pickups throughout the US.

Vestiaire Collective this week published its first impact report, created in partnership with PwC. The report reveals that only 10% of sellers on the platform use the takings from their sales to buy new clothes and accessories, and that 70% of sales made prevented a first-hand purchase, pointing to the potential of resale to prevent overconsumption.

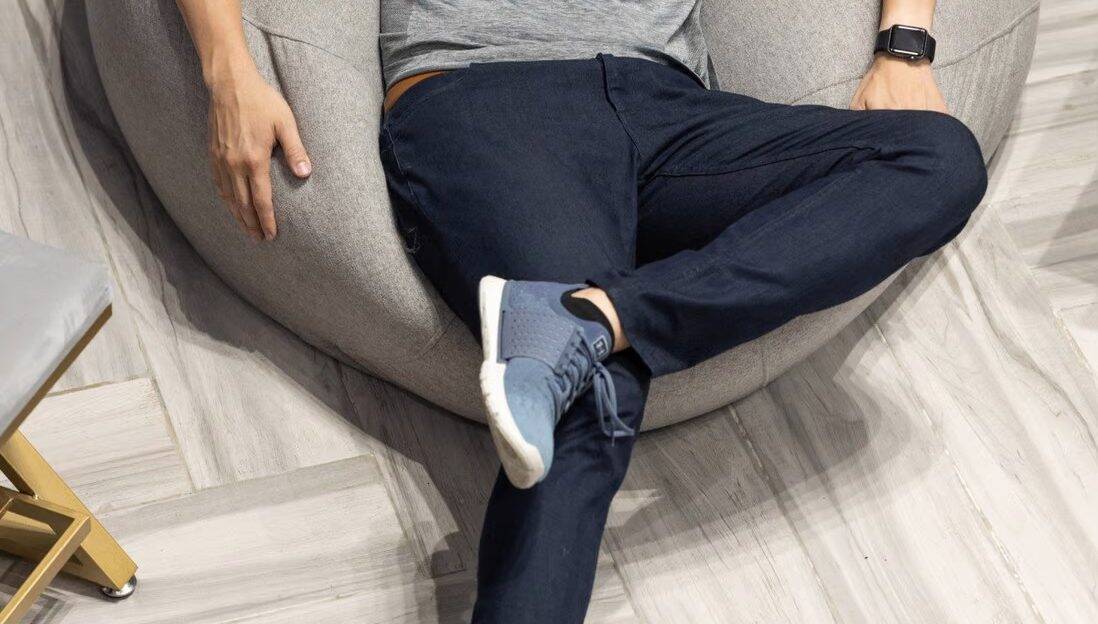

Bag repair services

Image: Ownever

As more people become aware of the huge amount of waste generated by the fashion industry, ‘slow fashion’ has begun to pick up steam. This global movement aims to break the wasteful cycle of throwaway clothes by encouraging people to only buy what they need – and to make items last as long as possible.

One Portuguese luxury brand, Ownever, is contributing to slow fashion by offering repairs for both its own bags, and bags from any other brand. The company can change the bag’s colour, fix the handles, remove mould, mend worn corners and eliminate leather stains.

Ownever claims that its bags are built to last forever and that it stays away from seasonal, trend-led design. Nonetheless, bags may sometimes become damaged, or their owners may want a change of look without buying new again.

Plastic-free faux leathers

Image: LOVR

Fur has been banished by fashion giants such as Versace, Prada, Gucci, and Burberry for some time now. But even as consumers demand greater sustainability and an end to animal cruelty, the fashion industry has found it harder to wean itself off leather.

One issue is that many faux-leather products are made from plastics, such as polyurethane and polyvinyl chloride (PVC), which themselves have a negative environmental impact. Bio-based leathers have the potential to solve this problem. They are made from an eclectic range of materials – from apples and pineapples to cork. Now, German startup LOVR has added hemp to the list of unlikely leather alternatives.

Agricultural residues from farms that grow the crop for CBD products form the basis of the LOVR material – which is billed as the world’s first 100% plant-based, and completely plastic-free leather alternative.

Recyclable, low-water, plastic-free fabrics

Image: Meryl Fabrics

Natural fabrics like cotton are often marketed as sustainable fabrics. However, current methods for producing cotton fibres can be water-intensive and wasteful – with production waste as high as 22% in some cases. Moreover, cotton is often used in blends with synthetics, leading to microfibre and microplastic shedding.

High-tech textile manufacturer Meryl Fabrics is tackling these issues with a range of sustainable cotton-touch fabrics and silky-touch yarns manufactured using advanced hydrogen technology.

The fabrics are infinitely recyclable, Meryl Fabrics claims, and the manufacturing process for the range uses no water – saving up to 3,000 litres for each 600m2 of fabric compared to traditional cotton fibre production methods. All products in the range are described by the company as ‘non-shedding’ – meaning that they do not release microplastics or microfibres. Weaving and cutting waste that accumulates during manufacturing can also be reused for new yarns.

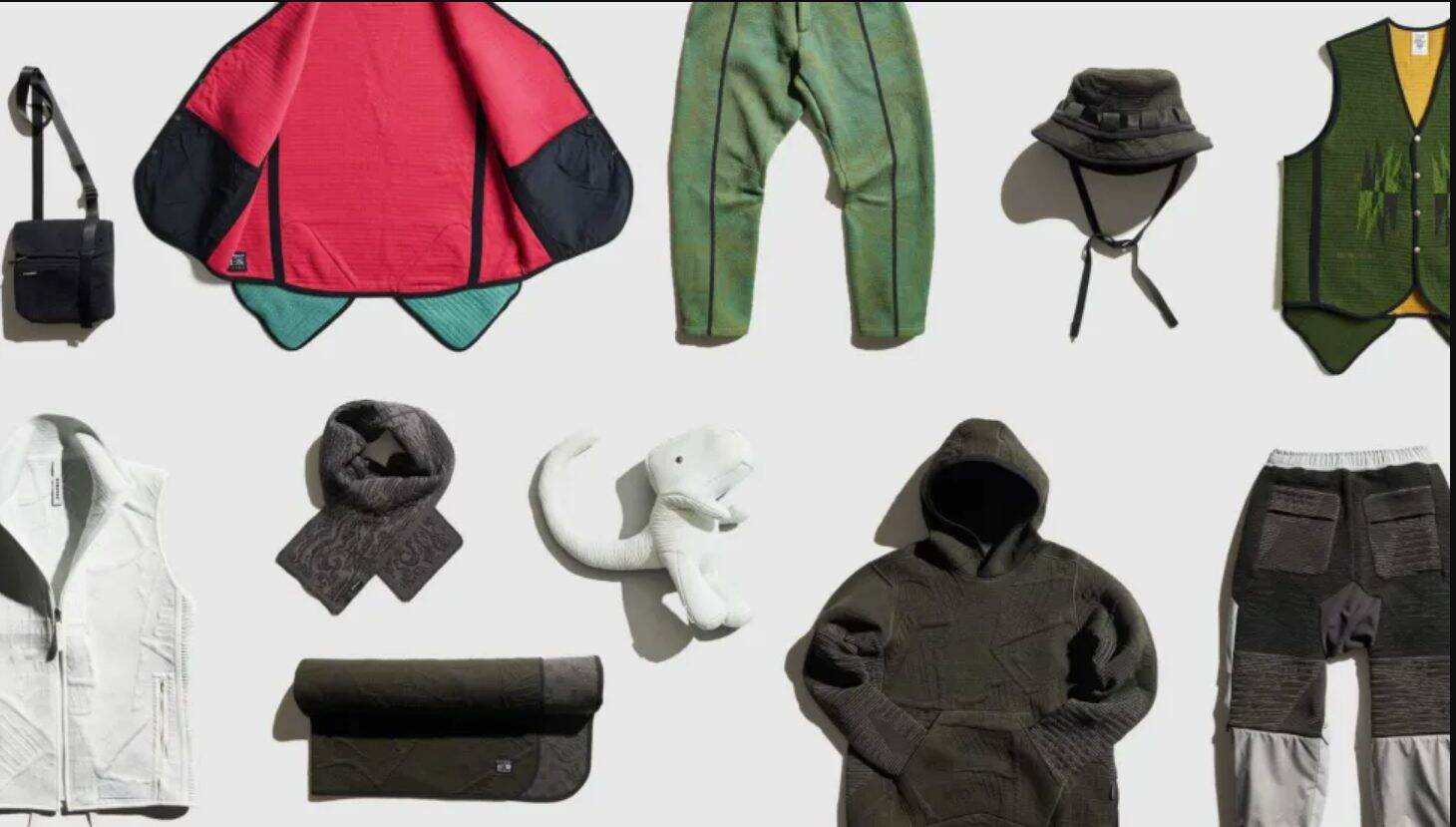

Algae is the new (carbon) black

Image: Vollebak

The production of carbon black—the pigment most commonly used for black clothing dyes—is extremely harmful to the environment. To extract the pigment from petroleum stored beneath the ground, it is common practice to strip large plots of land of all vegetation and animal life. Now, London-based tech clothing startup Vollebak is exploring alternatives to this unsustainable practice.

The company has launched a t-shirt—made from eucalyptus—that uses an ink made from black algae in place of carbon black. The t-shirt feels and looks just like a conventionally dyed t-shirt without any of the unsustainable practices present in traditional black dyes.

Black algae grows in ponds and captures carbon dioxide through photosynthesis when alive. The black algae t-shirt biodegrades in around 12 weeks, and once the fabric decomposes, the black algae ink remains – locking away the captured carbon within it for up to 100 years.

Digital textile design systems with sustainability built-in

Image: Byborre

Around 80% of the environmental footprint of textile production is set during the design process. Dutch textile label Byborre aims to address this problem with its new ‘Create’ product.

Create is a digital platform for designing complex, 3D-knitted textiles. The platform gives designers control over not only the design, colours, and properties of the textiles, but also over their environmental impact – allowing them to make adjustments. Users choose the properties they want—such as UV protection or odour resistance—before creating a colour palette and uploading or creating their own designs.

One of the key benefits of Create is that it lets designers see how colours will blend and products will look before manufacture – reducing waste, lowering costs, and speeding up the design process. The platform is also linked to a library of suppliers and manufacturers, so designers can find the right partners to responsibly produce their designs.

Springwise is the global innovation intelligence platform for positive and sustainable change. With a growing database of 11,000+ innovations, we are the place of record for innovation that matters. Visit Springwise.com for more information.

edie Staff and Springwise Staff

Please login or Register to leave a comment.